Garage Door Chock

Garage door safety and... style?

Our 1950’s home has its original garage door, track, and spring. The whole thing has aged well despite neglect, but it can’t fully resist gravity any longer. It also has been painted several times over the years and is really in need of a full restoration. Since we have plans to rework the garage in the not too distant future I’m not taking on that project (now) and have been just making do with the fact the garage door doesn’t always hold itself up anymore.

For the last 18 months the fix has been a screwdriver tied near the door with string, which we can insert through a hole in the track to act as a pin to prevent the door from falling. In terms of quick fixes for common life problems, this one isn’t bad but it’s not without some annoyances. The biggest is that the string sometimes gets caught up in the door mechanism and the screwdriver gets flung around and could take out an eye.

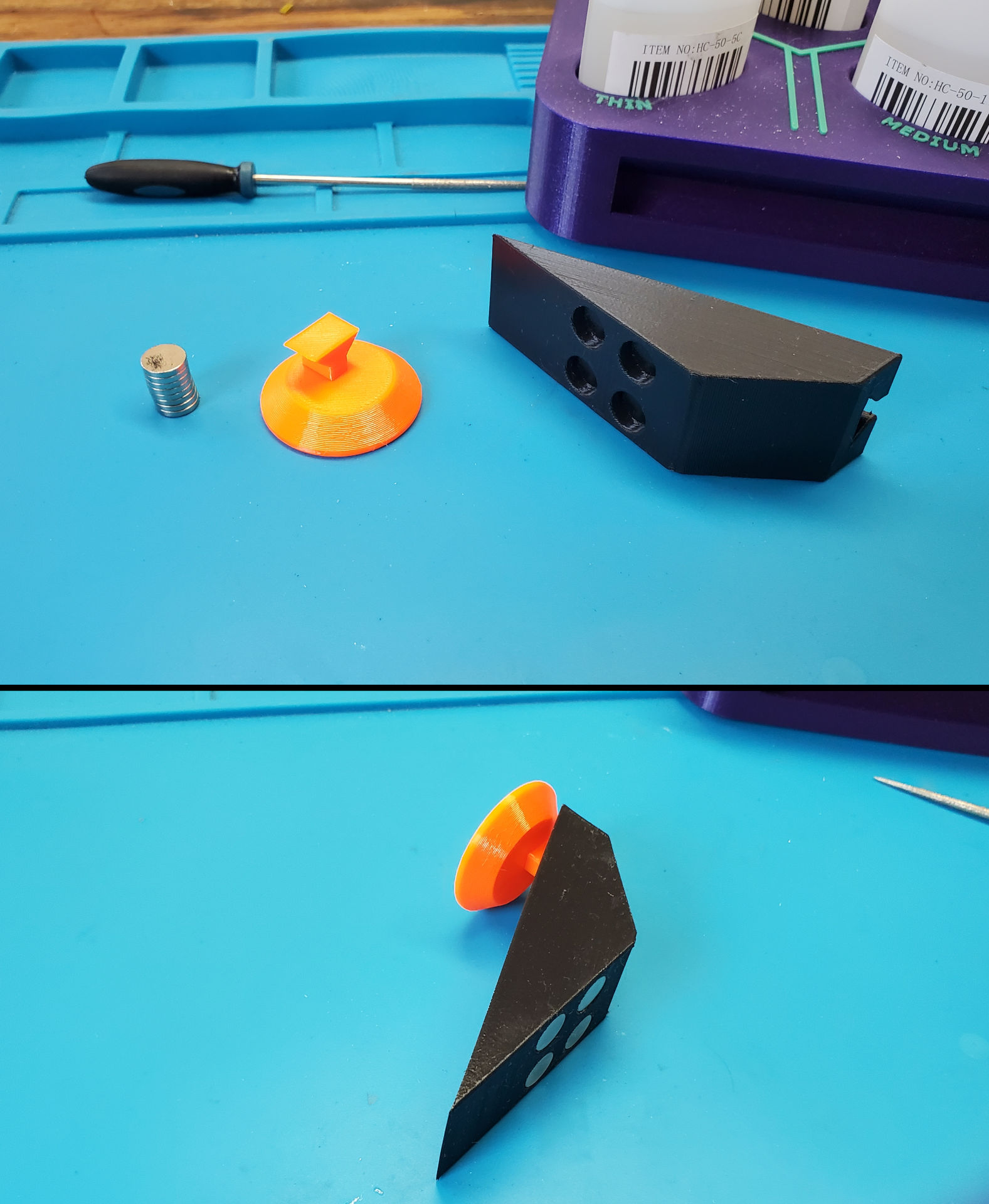

So I made a threw together this chock out of TPU with a small PETG handle.

Description

I put magnets in the base for two purposes. First, when the door is closed its convenient to be able to attach the chock to the door lock assembly as storage. Second, it hold the chock in place against gravity until the force of the wheel pushing the chock against the track lets friction do most of the work.

- Wedge is deep enough to more than accommodate all the horizontal wheel movement that the door track allows.

- Eight 10mm x 2mm rare earth magnets (4 stacks of 2 magnets) for holding strength.

- Easy printing.

- Handle prints separately attaches with a dovetail

- No supports or tricky overhangs

- Assembles with superglue.

Print Settings

- 0.2mm layer height

- 10% infill

- 3 perimeters

I used TPU that is Shore 40D hardness. I think something a bit softer (but not all the way to Ninjaflex) would have been better. I printed the handle in PETG because it’s what I had in the printer at the time.

I made mine with a debossed monogram on the handle. I have also included an STL without it.

Assembly

I made this using 10mmx2mm magnets because it’s what I had on hand. Since I needed a bit more uumph I stacked two magnets into each of the four holes (8 total magnets). With rare earth magnets I always like to use a file to scuff the surfaces of the magnets before I glue them in. I also used thin CA so it’s really get into the nooks and crannies.

I also glued the handle to the ramp. I use rubberized superglue here, but I don’t really think it was needed. I put the glue on the ramp: some on the bottom of the dovetail and some on the backstop that keeps the handle from sliding out the front side of the ramp. A little glue goes a long way.

Parts

- (8) 10mmx2mm neodymium magnets

- (1) Printed handle

- (1) Printed ramp

- (some) Glue, super

Tools

- A file or course sandpaper for distressing magnet surfaces (optional)